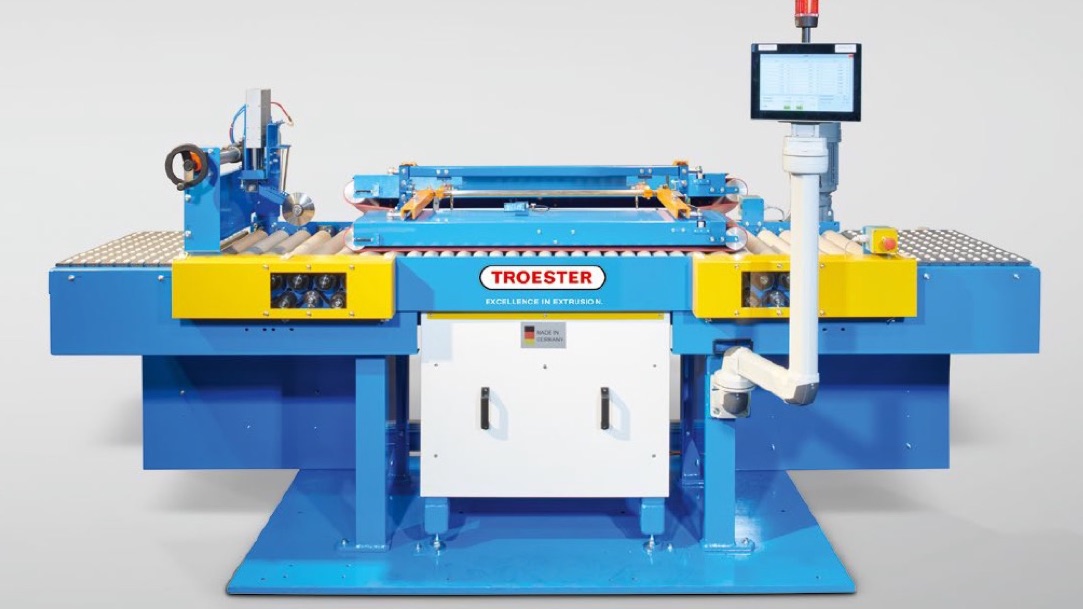

TROESTER WEIGHSCALE

The Troester Weighscale allows precised temperature control and stabilisation of measurement equipment during on line production. The Weigh Scale is equipped with an OPC data interface to have the device controlled by the line control system. During measuring process, endless material is weighed by passing a non-driven roller conveyor that is mounted on load cells with substructure for extruder and line control regulation.

Highlights

-

commercial and highest-accuracy in-house build systems

-

Facts and Figures

-

Benefits for our customers

-

Option WeighScale+

-

Option WeighScale+C

Downloads

-

Weigh Scale

- 101.5KB

Contact us

-

![Tire-measurement-systems]()

Mr. Karsten Jung

Director Sales Rubber