Extrusion Lines with Infrared Curing for Silicone Cables

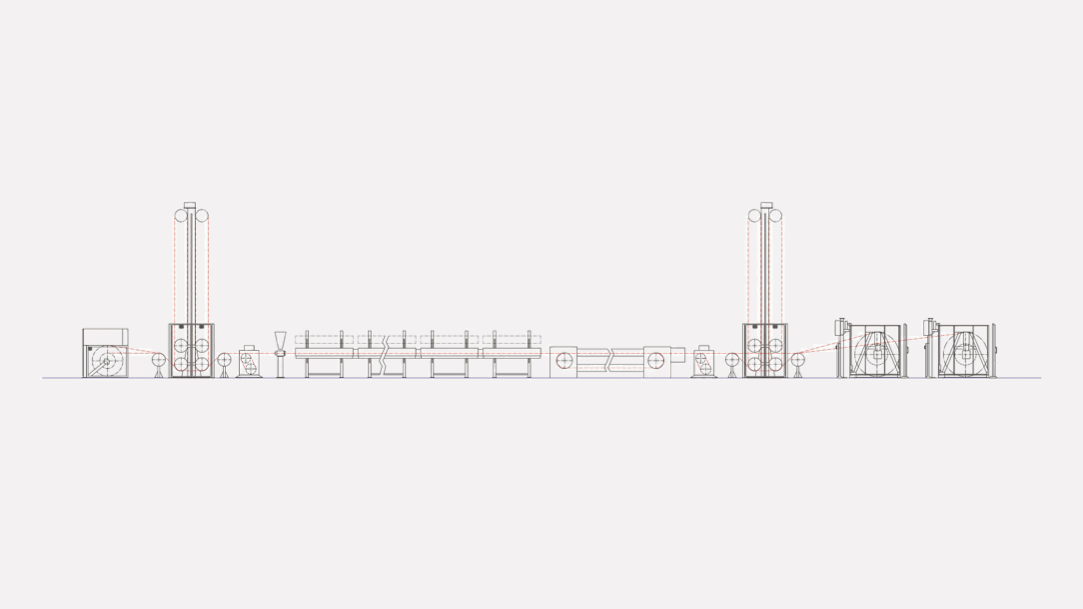

Silicone cables are used for applications with the demand for high temperature resistance and flexibility. TROESTER Extrusion Lines with Infrared Curing process all kind of silicone materials at high output combined with excellent melt quality.

Highlights

-

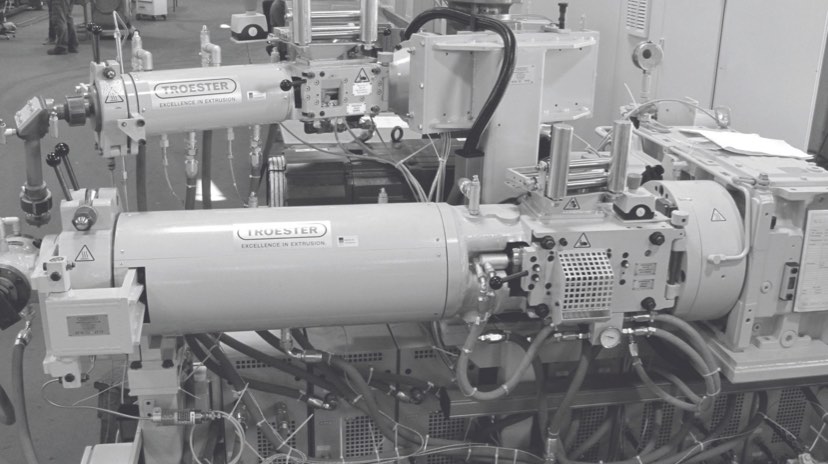

Silicone Extruder

-

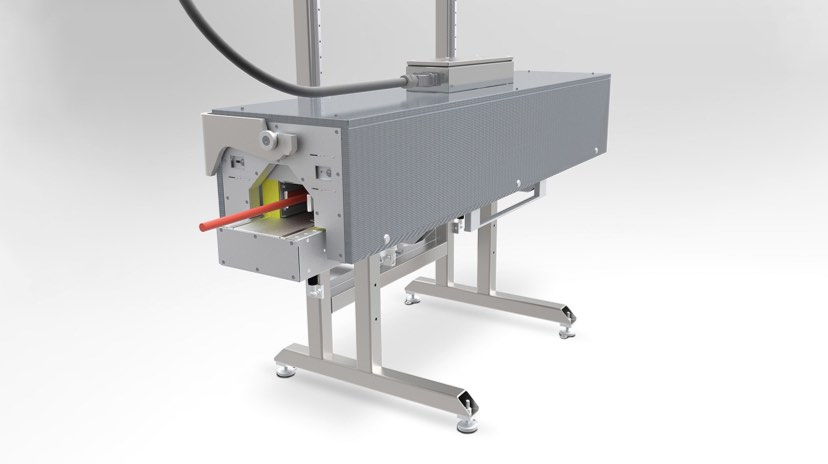

Infrared Curing Oven TRIOX

Downloads

-

Extrusion Lines for Silicone Cables

- 1.1MB

-

Extruders for Rubber Cables

- 614.3KB

-

Single cross heads and Double Cross Heads

- 417.3KB

-

Portal Winders

- 836.2KB

-

Spool Winders

- 344KB

-

Belt-type Caterpillars

- 309.3KB

-

Accumulators

- 369KB

-

Electrical Equipment for the Cable industry

- 1.3MB

-

Industry 4.0

- 509.4KB

-

Extrusion Equipment for the Cable Industry

- 5.2MB

Contact us

-

![extrusion-lines-infrared-big]()

Mr. Dirk Schmidt

Director Sales Cable